Advantages Of Hydrocracking Reaction

A review of recent advances in catalytic hydrocracking of heavy residues. Oil-soluble manganese and molybdenum catalysts for a hydrocracking reaction. In this process, coke formation was. During this process, sedimentation is reduced in the reactor. The advantages of this process are, prolonged the catalytic activity, feed.

Author: Vincenzo Piemonte, Associate Professor, University UCBM – Rome (Italy) 1.Theme description Worldwide economic growth continues to drive demand for transportation fuels, and in part There are several processes presently able to meet individual refinery needs and project objectives. In particular, UOP LLC Company is one of the most active society in this field. The basic flow schemes considered by UOP are single-stage or two-stage design. UOP two-stage Unicracking process flow schemes can be a separate hydrotreat or a two-stage process as shown in Figure 1. In the separate hydrotreat flow scheme the first stage provides only hydrotreating while in the two-stage process the first stage provides hydrotreating and partial conversion of the feed. Zombie panic source hacks.

The second-stage provides the remaining conversion of recycled oil so that overall high conversion from the unit is achieved. These flow schemes offer several advantages in processing heavier and highly contaminated feeds. Two-stage flow schemes are economical when the throughput of the unit is relatively high. The design of hydrocracking catalyst changes depending upon the type of flow scheme employed. The hydrocracking catalyst needs to function within the reaction environment and severity created by the flow scheme that is chosen.

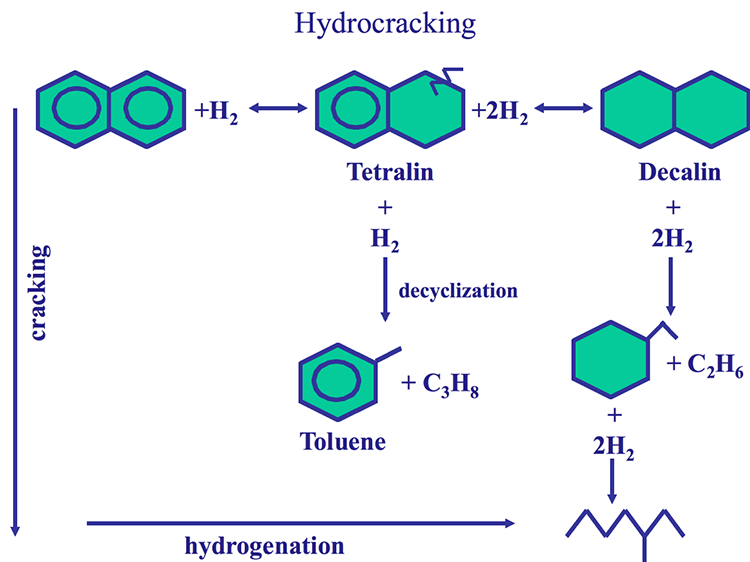

2.Enhanced Hydrocracking Processes During the early years of hydrocracking, refiners were mainly interested in maximizing production of naphtha for reforming to high octane gasoline. However with advancements in hydrocracking catalyst technology, and the demand for maximizing distillate yields from heavier feedstocks, two-stage design offers a cost-effective option for a larger capacity maximum distillate unit operation. A major difference between the first and second stage hydrocracking reactor reaction environments lies in the very low concentrations of ammonia and hydrogen sulfide in the second-stage (see figure 2).

Reno sa Volvo motorom (Magnum ili Premium) nisu problem motori ali ostalo je pod znakom pitanja imao sam slučaj da smo Premiuma 385 dci pre mesec dana morali da šlepamo sa bukvalno same rampe na granici RO-UA. Servis Kompjutera Ceklin Elektronika. Professional Service. Reno Srbija Renault Srbija. Higgins Premium Pet Foods. Pet Supplies. Jobin Joseph. Prikazano 12 od 12 oglasa. Mojauto.rs je vodeci portal za prodaju polovnih automobila i drugih auto oglasa u Srbiji. Kupite ili prodajte svoj polovan automobil ili drugo vozilo brzo i efikasno na Mojauto.rs. أفضل حل للقضاء على الفئران| أصنع بنفسك فخ للفئران بأستخدام CoCa CoLa Cans أفضل من أي وقت مضى - Duration: 8:39. إنسان 17,971,615. Oshibki kompjyutera reno premium.

The first-stage reaction environment is rich in both ammonia and hydrogen sulfide generated by hydrodenitrogenation and hydrodesulfurization of the feed. This significantly impacts reaction rates, particularly cracking reaction rates, leading to different product selectivity and catalyst activity between the two-stages. The catalyst system can be optimized to obtain a highly distillate selective overall yield structure. Optimum severity can be set for each stage to achieve catalyst life target with minimum catalyst volume.